WT series gas turbine flowmeter

WTD series gas turbine flowmeter

WT series gas turbine flowmeter is a high-precision, high-reliability precision measuring instrument. It is suitable for the measurement of various single-phase gases and the measurement of gas in urban gas, petroleum, chemical, electric power, metallurgy and other industries.

WT series gas turbine flowmeters have excellent low-pressure and high-pressure measurement performance, suitable for accurate measurement of large flow gas. According to user needs, our company can provide turbine flowmeters with different accuracy levels and different performances.

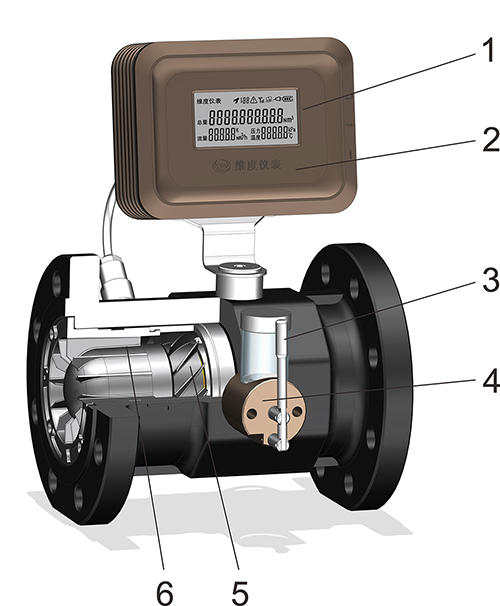

Figure 1 Turbine flowmeter

1: display 2: volume correction instrument 3: flow meter housing 4: oil pump 5: turbine 6: pilot fluid

Technical Performance Index

1. Executive Standard

a. WT series gas turbine flowmeter implements the verification procedure of JJG 1037-2008 "Turbine Flowmeter"

b. Implement the enterprise standard of Q/WD 001-2018 "WTE Gas Turbine Flowmeter"

c. Implement the national standard GB/T 18940-2003/ISO9951:1993 "Measurement of gas flow meters in closed pipelines and turbine flow meters"

d. Implementation of GB/T28848-2012 "Smart Gas Flowmeter" national standard

1.1 Product type test verification number 2019F305-33.

2. Accuracy class

a. Use the high repeatability of the turbine flow sensor to linearly correct the meter coefficients (normally no correction is required). The accuracy level within the range is:

Level 1.0 and 1.5. If no linear correction is performed, according to the ISO9951 international standard:

1.0 level: 0.2Qmax~Qmax: ±1.0%; Qmin~0.2Qmax: ±2.0%

1.5 level: 0.2Qmax~Qmax: ±1.5%; Qmin~0.2Qmax: ±3.0%

b. Temperature indication error: ≤±0.5%

c. Pressure indication error: ≤±0.2% (≥20%Pmax) (upper limit of pressure sensor range Pmax: 0.2, 0.5,

3. Mechanical performance index

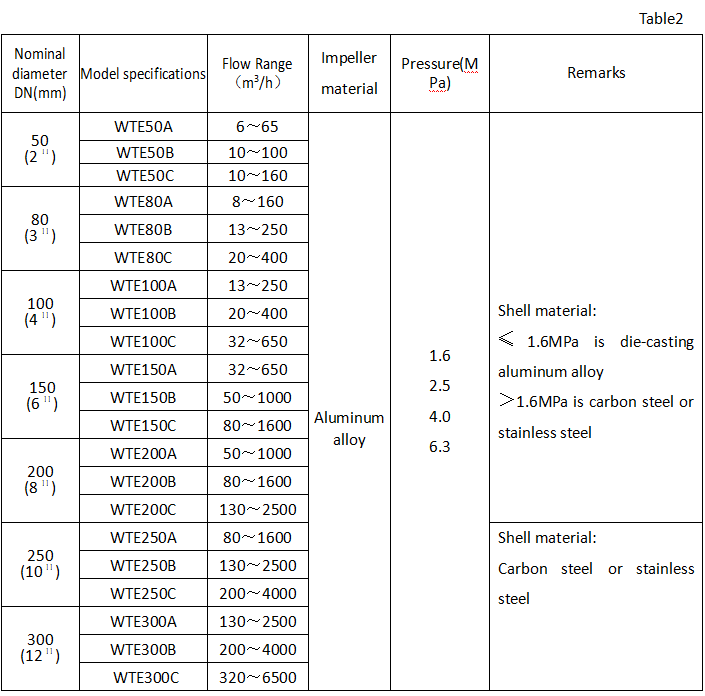

3.1 Flowmeter model specifications, basic parameters are shown in Table 2.

Note:

① The flow range listed in the table is the flow range of the product at the factory inspection (the medium is air at normal temperature and normal pressure);

② As the pressure increases, the flow range also expands.

Main features High accuracy, good repeatability, wide range ratio (up to 1:20) Using integrated rectifiers, lower requirements for front and rear straight pipe sections (front ≥2DN, after ≥1DN) The volume corrector of the flowmeter can freely rotate about 360°, which can be easily read in various installation modes Low speed, long life, low pressure loss, high precision Using high-precision digital temperature sensor and digital pressure sensor, and the digital pressure sensor comes with temperature compensation correction function, high pressure detection accuracy, good long-term stability, low temperature drift It can automatically detect the temperature and pressure of the medium, and correct the temperature, pressure and compressibility factor, and convert the volume flow and total volume under working conditions to the volume flow and total volume under standard conditions. Using advanced micro-power high-tech, low power consumption, long-term operation with internal battery power Adopt large-capacity data storage, with data tamper-proof function, automatically record key data modification and historical data With real-time data storage function, it can prevent data loss when the battery is replaced or power failure. In the case of power failure, the internal parameters can be permanently saved It can be embedded with wireless modules such as GPRS or NB_IOT to form a variety of wireless meter reading systems. It is powered by a built-in battery to achieve a limited number of wireless transmissions (once a day) without external power supply, which is convenient to use;